The 6795-CL is a two-flavor countertop frozen beverage machine built for ultra-high-volume applications that demand maximum output and reliability. With patented freezing technology and dual 7.3qt cylinders, the 6795-CL achieves rapid freeze-down and recovery times, producing up to 120 quarts per hour, or 480 (8oz) drinks. Pre-cooling in the hoppers refrigerates product before it enters the freezing cylinders, further reducing freeze times while earning food safety approval for overnight storage, including dairy-based mixes. Dual controls allow operators to serve two different products simultaneously, making it easy to expand menus with shakes, smoothies, frozen coffee beverages, margaritas, or cocktails. Its low evaporator temperature also makes freezing alcoholic beverages effortless, offering versatility across high-demand environments.

At the core of its performance is Spaceman’s patented 100% Controlled Contact Flooded Evaporator, engineered for maximum efficiency to deliver the industry’s fastest freeze-down and recovery times with smaller ice crystals and the smoothest, creamiest texture. Continuous improvements in design, informed by operator feedback and R&D, enhance structural integrity, improve serviceability, and reduce failure points for long-term reliability.

The single-piece V3 auger combines the drive shaft and auger into one solid over-molded plastic and steel assembly, reducing parts, simplifying cleaning, and improving durability. By scraping the cylinder walls with precision and controlling product flow, it consistently produces smaller ice crystals and smoother drinks. Operators can switch products and hardness levels in under 30 seconds using the overhead design, while the 1–6 consistency setting makes it simple for multi-unit operators to standardize performance across locations.

Additional operator-focused features include an RGB display with a low-level indicator that flashes red when product is running low, and a low-mix freeze protection system that automatically switches the machine to standby mode when mix runs out. Backlit virtual merchandising provides a high-visibility illuminated display area with interchangeable flavor cards, offering prime branding and marketing opportunities with custom dimensions available. Separate hopper cooling controls allow each hopper to be managed independently, preventing sidewall freezing and pre-chilling product for improved cylinder efficiency. The increased 5-gallon hopper capacity supports larger batch mixing and fewer refills, further boosting efficiency in high-volume operations.

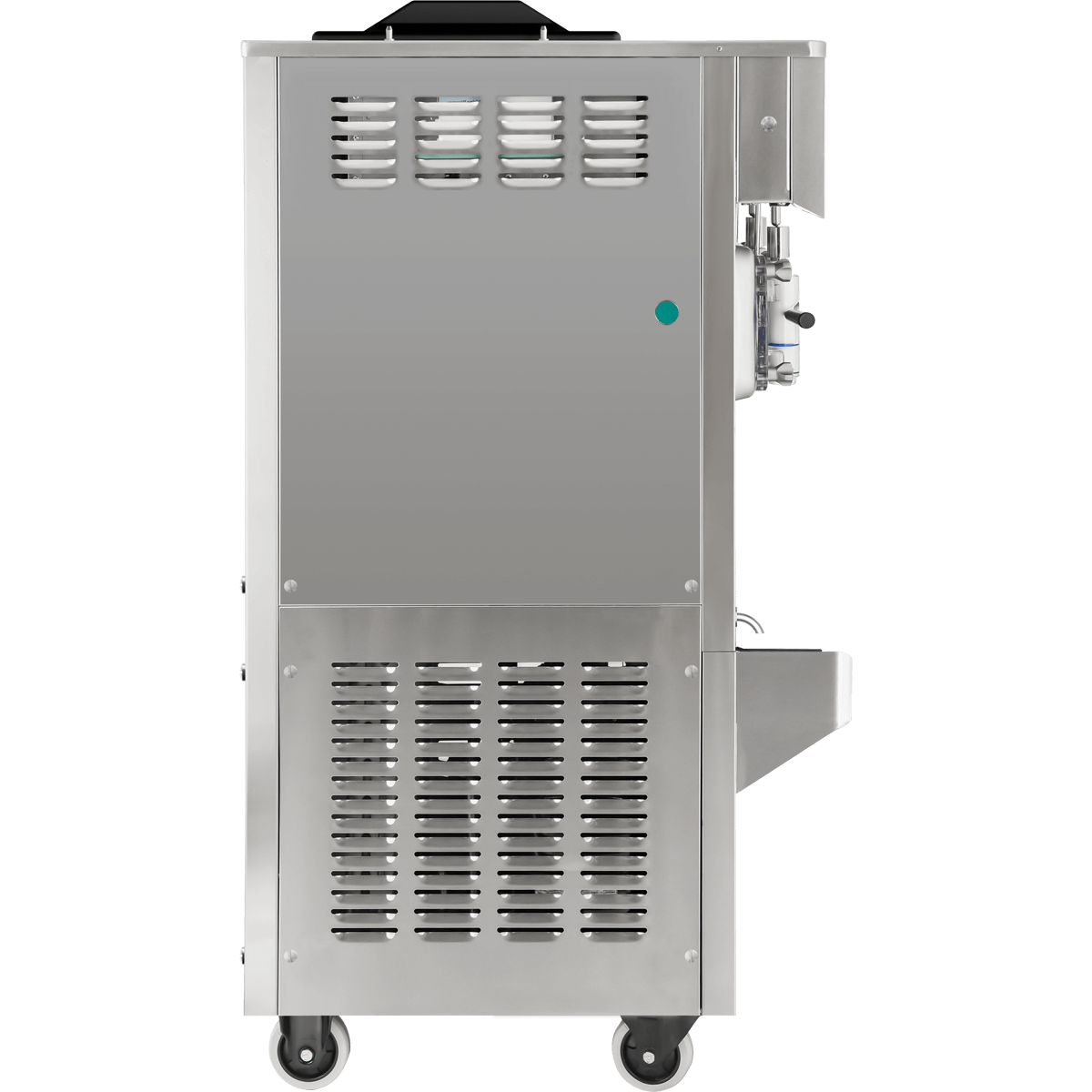

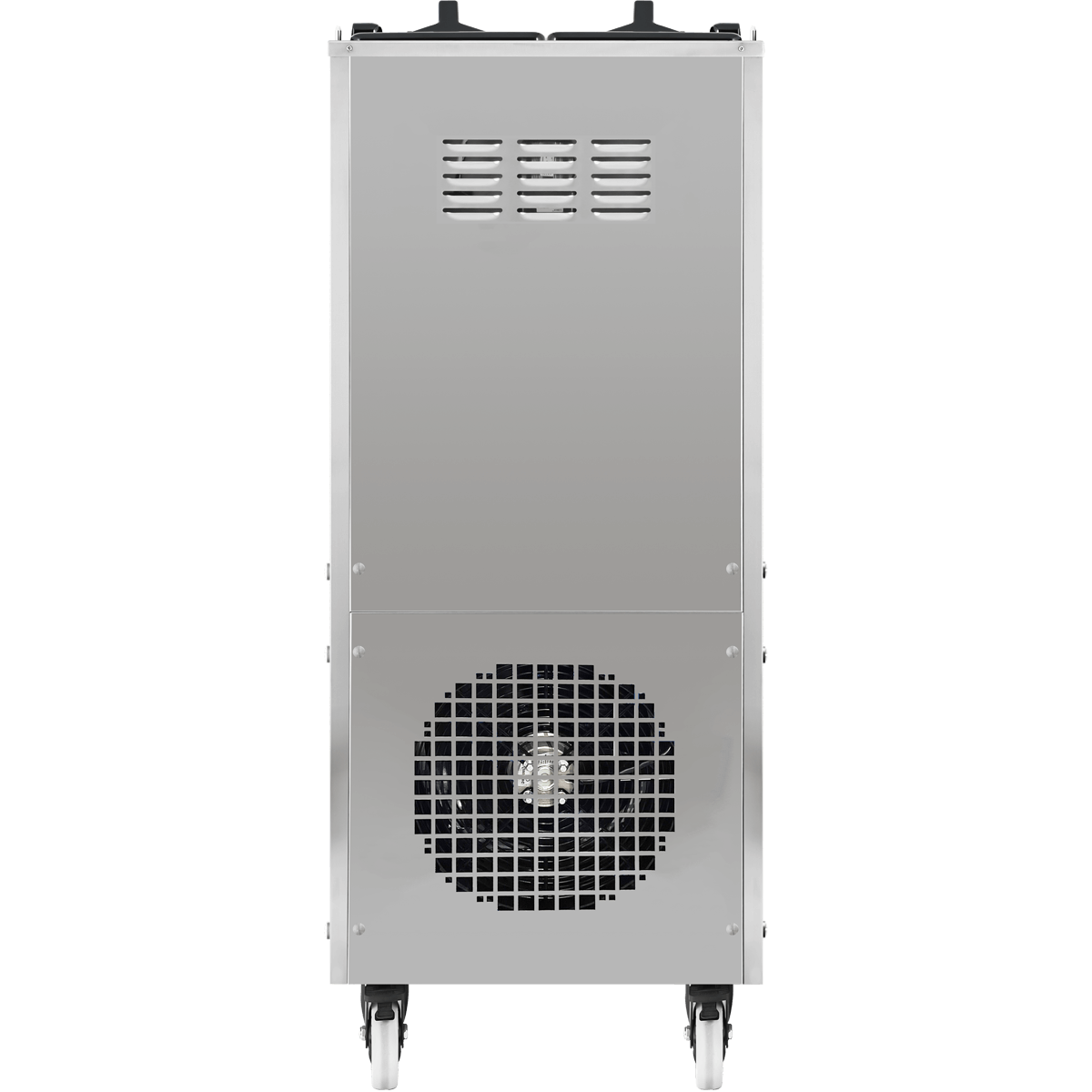

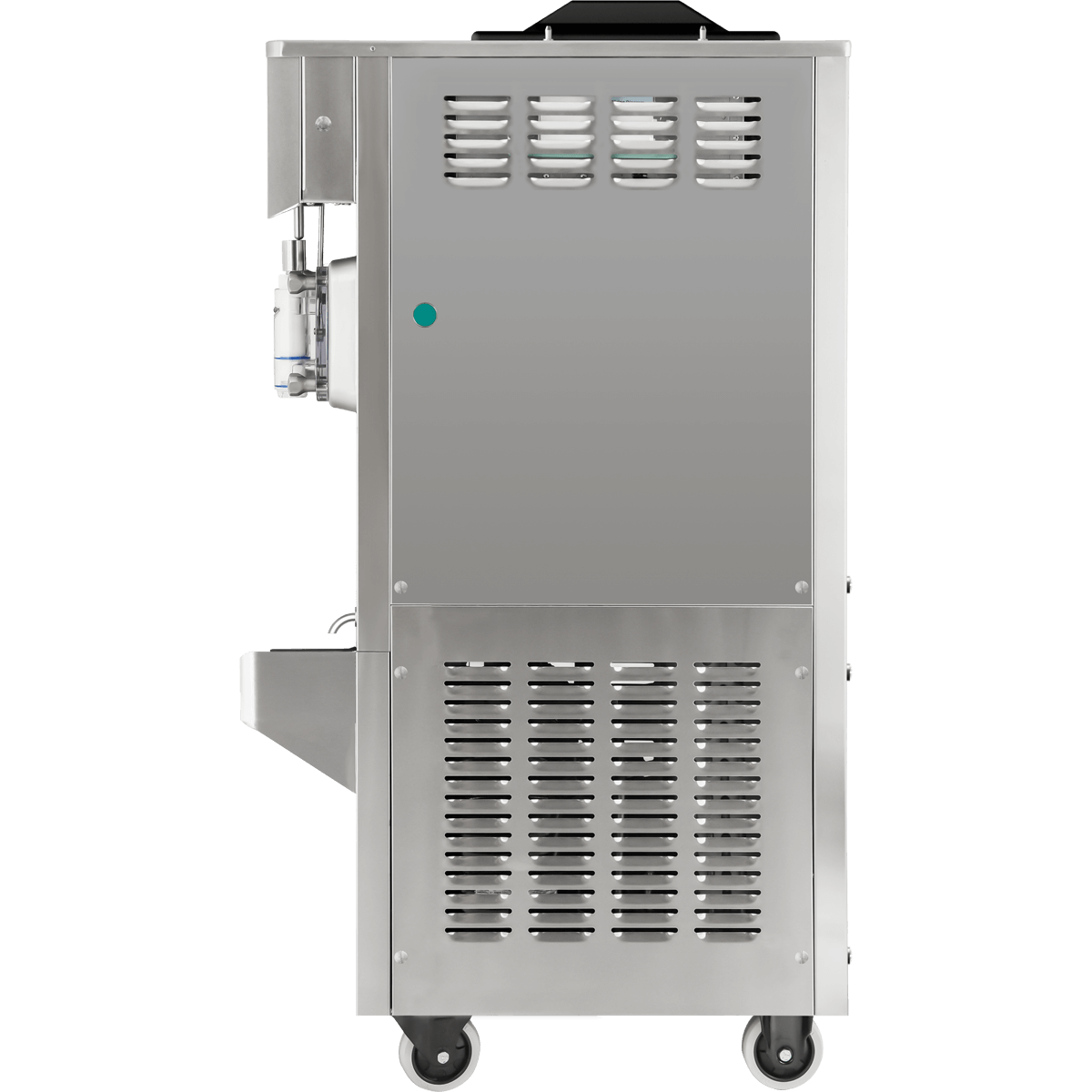

Engineered with a powerful drivetrain and advanced control mechanism, the 6795-CL is built to handle the heavy demands of milkshakes and frozen beverages, ensuring smooth operation and consistently rich, creamy results with every pour. For added convenience and mobility, it comes equipped with four heavy-duty rotating and locking caster wheels and an eight-foot cord and plug, making it easy to position and operate in any environment.